The sword, a weapon steeped in history and symbolism, remains an object of fascination and reverence in modern times. While its practical application in warfare has largely diminished, the art of swordmaking continues to evolve, blending centuries-old traditions with cutting-edge technology and design principles. The process of crafting a modern sword is a delicate dance between honoring the past and embracing the future, resulting in blades that are both functional works of art and testaments to the enduring allure of this iconic weapon.

The Foundation: Understanding the Sword’s Purpose and Context

Before the first spark flies from the forge, a skilled swordsmith embarks on a journey of research and contemplation. The design process begins with a deep understanding of the sword’s intended purpose and context. Will it be a graceful katana for martial arts practice, a robust longsword for historical reenactment, or a fantastical blade for cosplay or display? Each purpose demands specific considerations regarding blade geometry, weight distribution, and overall aesthetic.

Furthermore, the swordsmith must consider the historical and cultural context in which the sword will exist. A replica of a medieval arming sword, for example, may necessitate adherence to specific metallurgical techniques and design elements to ensure authenticity. Conversely, a contemporary art sword may offer greater freedom for artistic expression and experimentation.

This article may interest you. The Fascinating Types of Swords Throughout History

The Blueprint: Designing the Blade and Hilt

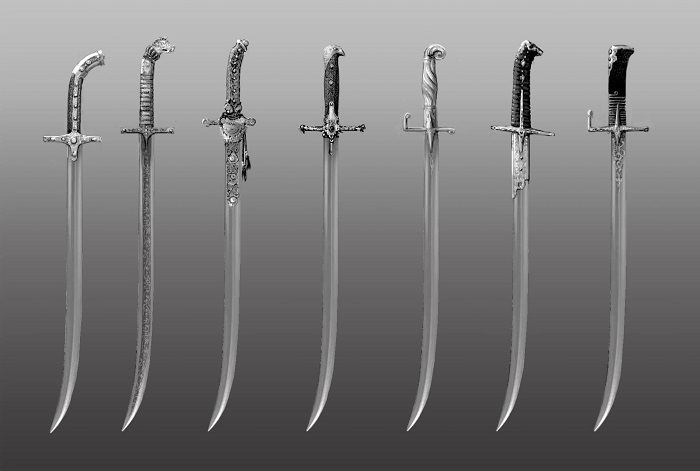

Once the purpose and context are established, the swordsmith translates their vision into a detailed blueprint. This blueprint encompasses both the blade and the hilt, each playing a crucial role in the sword’s overall functionality and aesthetic appeal.

The blade’s design is a symphony of curves and angles, each contributing to its cutting performance, balance, and durability. The choice of steel, the forging process, and the heat treatment protocol all influence the blade’s final properties. Modern swordsmiths often employ advanced metallurgical techniques, such as differential hardening and selective tempering, to create blades that are both resilient and capable of holding a keen edge.

The hilt, comprising the guard, grip, and pommel, provides the interface between the sword and its wielder. It must offer a secure and comfortable grip while facilitating precise control and maneuverability. The hilt’s design is often informed by ergonomic principles and aesthetic preferences, with a wide array of materials and decorative motifs available to personalize the sword.

The Forge: Transforming Raw Materials into a Blade

With the blueprint in hand, the swordsmith ventures into the forge, where raw materials are transformed into a gleaming blade. The process typically begins with the selection of high-quality steel, carefully chosen for its specific properties. The steel is then heated in a forge and shaped through a series of hammering, folding, and grinding operations. This laborious process refines the steel’s grain structure, enhances its strength, and removes impurities.

Modern swordsmiths often employ power tools and precision machinery to augment their traditional hand-forging techniques. This allows for greater efficiency and consistency while maintaining the artistry and craftsmanship inherent in the process.

The Heat Treatment: Tempering the Blade’s Spirit

Once the blade has taken shape, it undergoes a critical heat treatment process that determines its final mechanical properties. This process involves carefully heating the blade to specific temperatures and then rapidly cooling it in a quenching medium, such as oil or water. The quenching process hardens the steel, making it more resistant to deformation and wear.

However, the hardened steel is also brittle and prone to fracture. To alleviate this brittleness, the blade is tempered by reheating it to a lower temperature and then allowing it to cool slowly. The tempering process reduces the steel’s hardness slightly but significantly increases its toughness and resilience.

The heat treatment process is a delicate balancing act, requiring precise control of temperature and time. A skilled swordsmith understands the nuances of different steel alloys and can tailor the heat treatment protocol to achieve the desired balance of hardness, toughness, and flexibility.

The Finishing Touches: Polishing and Sharpening

After the heat treatment, the blade is meticulously polished to remove any imperfections and reveal its inherent beauty. The polishing process is both an art and a science, requiring patience, skill, and a keen eye for detail. Modern swordsmiths often employ a combination of hand-polishing techniques and specialized machinery to achieve a flawless finish.

Finally, the blade is sharpened to a razor-sharp edge, ready to fulfill its intended purpose. The sharpening process is a delicate operation that requires precision and expertise. A well-sharpened blade is not only capable of delivering devastating cuts but also enhances the sword’s overall aesthetic appeal.

The Assembly: Uniting Blade and Hilt

With the blade complete, the swordsmith turns their attention to the hilt. The guard, grip, and pommel are carefully crafted and assembled, often incorporating intricate details and decorative elements. The hilt is then securely attached to the blade, creating a harmonious union of form and function.

The assembly process requires meticulous attention to detail and a deep understanding of the sword’s intended use. The hilt must be perfectly balanced and aligned with the blade to ensure optimal handling and performance.

The Final Inspection: Ensuring Quality and Craftsmanship

Before the sword leaves the forge, it undergoes a rigorous final inspection to ensure that it meets the highest standards of quality and craftsmanship. The swordsmith carefully examines the blade and hilt, checking for any imperfections or inconsistencies. The sword is also tested for balance, handling, and cutting performance.

Only when the swordsmith is completely satisfied with its quality and craftsmanship is it deemed ready to be presented to its new owner.

Conclusion

The process of modern sword design is a testament to the enduring legacy of this iconic weapon. It is a delicate dance between tradition and innovation, honoring the past while embracing the future. The resulting blades are not only functional works of art but also symbols of the human spirit’s unwavering pursuit of excellence and beauty.

In the hands of a skilled swordsmith, raw materials are transformed into objects of power, grace, and timeless allure. Each sword tells a story, woven from the threads of history, culture, and individual expression. The modern sword is a testament to the enduring power of the human imagination and the boundless possibilities that emerge when tradition and innovation intertwine.